| Model | ZR-1000 |

| Production | 1000L/Batch,Up to 4 batches/day |

| Capacity | Effective volume: 1000L |

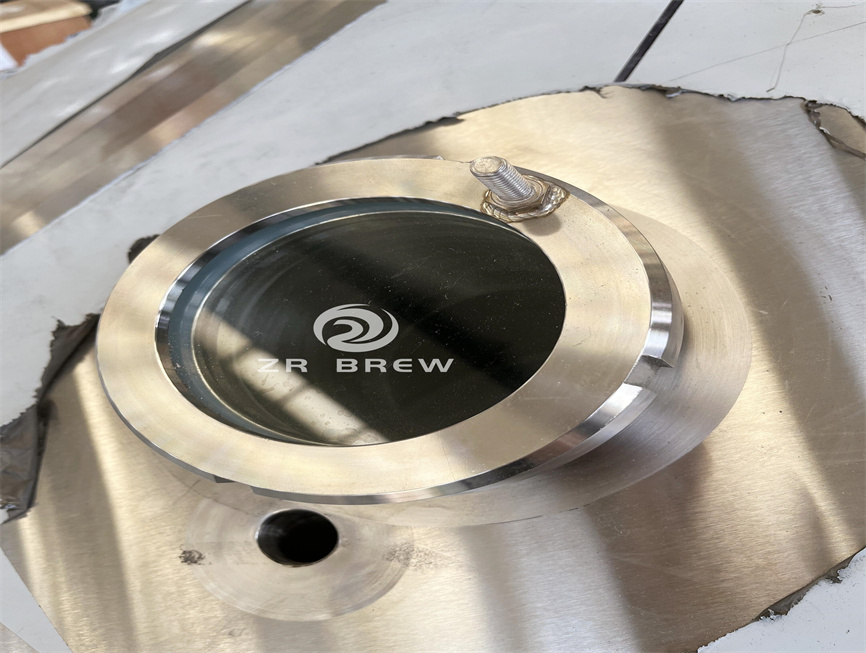

| Material | SUS304 SUS316 |

| Combination method | 2-Vessel 3-Vessel 4-Vessel 5-Vessel |

| Application | Restaurant Bar Hotel Brewery |

| Heating way | Electric heating Steam heating Direct fire heating |

| Control System | Fully automated with PLC Siemens Semi-Automated with PID Schneider |

| Voltage | Three-phase/380(220, 415,480…)v/50(60)Hz Single phase/220(110, 240…)v/50(60)Hz |

| power | 25KW |

| Water Consumption | 6T |

| floor space | 70-120 ㎡ |

| Note:1Barrel (BBL) =117 Liter 1Hl=100 Liter 1Gallon=3.7854 Liter | |

Advantage of Configuration

---------------------------------------------------------------------------------------------------------------------------------

▶ 3-vessel brewhouse can achieve 4 batches of brewing per day, laying a good foundation for the expansion of production

▶ Mixing unit for better mixing of grain and water

▶ The lauter tank tiller system and hydraulic automatic lifting technology can ensure the uniform and comprehensive filtration of the mash;

▶ The liftable scraper cooperates with the pneumatic gate valve to automatically discharge the waste;

▶ The wort loop pipe with multiple branch pipes to collect the wort more evenly;

▶ The backwash loop pipe with multiple branch pipes to solve the difficulty of filtration;

▶ Independent heater in the kettl for better boiling effect;

▶ Specially designed steam jacket device to improve steam utilization efficiency and avoid "water hammer" problem

▶ Special tank and pipeline structure to avoid wort aeration problem and reduce material loss

▶ The boiling process can be carried out under pressure, especially for breweries at higher altitudes.

▶ Specially designed steam condensing unit with both steam condensing and hot water recovery functions

▶ Reserve the cooling capacity and pipeline interface for future expansion;

▶ PID control is widely used in the brewing production process due to its simplicity, reliability, easy implementation, and good static performance.

1000L Brewing Equipment Standard Configuration

---------------------------------------------------------------------------------------------------------------------------------

Malt Milling Unit

▶ Grist case

▶ Particles adjustable counter-roll dry crusher or wet crusher

▶ Flexible or steel auger lifts milled grain directly to the mash bucket

Brewhouse System

▶ Mash tun, lauter tun, kettle tun and whirlpool tun 4-vessel combination;

▶ Two-stage or single-stage heat exchanger for wort cooling;

▶ Wort oxygenation device before entering the fermenter;

▶ Hygienic and high-efficiency mash pump with frequency conversion

▶ Sanitary stainless steel pipes and valves

▶ Quick-install and fully detachable stainless steel operating platform

▶ Special combination of brewing water tank, hot water tank and cold water tank can be selected

Fermentation System

▶ Stainless steel fermentation tank with cooling jacket

▶ Stainless steel bright tank or storage tank with cooling jacket

▶ The quantity and volume of fermentation tanks are accurately calculated by the fermentation cycle of various beers

▶ All orifices, valves, pressure gauges, safety valves, temperature probes, rotating arm beer outlet and other accessories are included

▶ Unitanks with carbon dioxide charging device with carbon fossil

▶ PPR pipes and stainless steel pipes with thermal insulation layer are available;

Glycol Cooling System

▶ Insulated glycol tank for glycol liquid holding and mixing

▶ The chiller or refrigerator is accurately calculated the cooling capacity according to the needs of heat exchanger and fermentation system

▶ Sanitary centrifugal pump powering glycol water circulation

▶ Other more energy-efficient options, such as adding a cold water tank

CIP Cleaning System

▶ A removable CIP cleaning system including lye tank and acid tank is available;

▶ Fixed CIP cleaning system including lye tank, acid tank and hot water tank is available;

▶ Simple mobile pump is available;

Control System

▶ PID semi-automatic control with temperature display, setting and control and pump start-stop control is available;

▶ PLC automatic control is optional; it has temperature, flow, liquid level display and control, accurate metering of feeding water and automatic mixing, editing and storage of recipes and one-key completion of the brewing process;

1000L Brewing Equipment Optional Configuration

---------------------------------------------------------------------------------------------------------------------------------

▶ Water treatment device for brewing water

▶ Gas or electric boilers for providing thermal energy;

▶ Filter press instead of filter tank;

▶ Waste grains conveying device with auger and grains storage tank

▶ Yeast culture system and yeast recovery system;

▶ Air compressor

▶ Tunnel pasteurization system or instant sterilization system;

▶ Packaging system for beer kegs, beer bottles and cans;

▶ Removable diatomaceous earth filter

▶ Tube sheets for centralized valve operation;

| Item | Production capacity(L) | Power(KW) | Water consumption(T) | Floor space(㎡) | Roof height(mm) |

| ZR-500 | 500L/Batch | Electric heating:55KWSteam / direct fire heating:10KW | 2.9 | 40-60 | 3000 |

| ZR-600 | 600L/Batch | Electric heating:60Steam / direct fire heating:15KW | 3.6 | 40-60 | 3200 |

| ZR-700 | 700L/Batch | Electric heating:65Steam / direct fire heating:20KW | 4.2 | 50-70 | 3200 |

| ZR-800 | 800L/Batch | Electric heating:70Steam / direct fire heating:20KWSteam / direct fire heating: | 4.8 | 50-70 | 3200 |

| ZR-1000 | 1000L/Batch | Electric heating:80KWSteam / direct fire heating:25KW | 6 | 70-120 | 3500 |

| ZR-1500 | 1500L/Batch | Steam / direct fire heating:130KW | 9 | 100-200 | 4100 |

| ZR-2000 | 2000L/Batch | Steam / direct fire heating:140KW | 12 | 150-250 | 4400 |

| ZR-2500 | 2500L/Batch | Steam / direct fire heating:150KW | 15 | 180-300 | 4900 |

| ZR-3000 | 3000L/Batch | Steam / direct fire heating:200KW | 18 | 200-350 | 4900 |

| ZR-5000 | 5000L/Batch | Steam / direct fire heating:300KW | 30 | 400 and above | 6000 |

What is the general reason for the beer machine not being able to make wine?

There are five reasons why you should not drink alcohol:

1. The carbon dioxide cylinder is empty, replace the cylinder

2. The dispenser is not opened Press the handle of the dispenser

3. The stainless steel coil freezes to death or partially freezes to death Check the thickness of the ice plate

4. Wrong connection of wine pipe Check whether the connection between the distributor and the stainless steel wine pipe is correct

5. There is no wine in the wine barrel, change the wine barrel

What factors need to be considered when choosing a set of bar beer brewing equipment

1. The consumption of beer

2. Site conditions

3. Estimated investment

4. Types of winemaking

5. Daily brewing batches

6. Brewing process

7. Wine selling equipment

8. The aesthetics of the equipment

Shandong Zeren Machinery Equipment Co., Ltd. is an equipment manufacturer focusing on biological fermentation industry

Copyright © Shandong Zeren Machinery Equipment Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support: