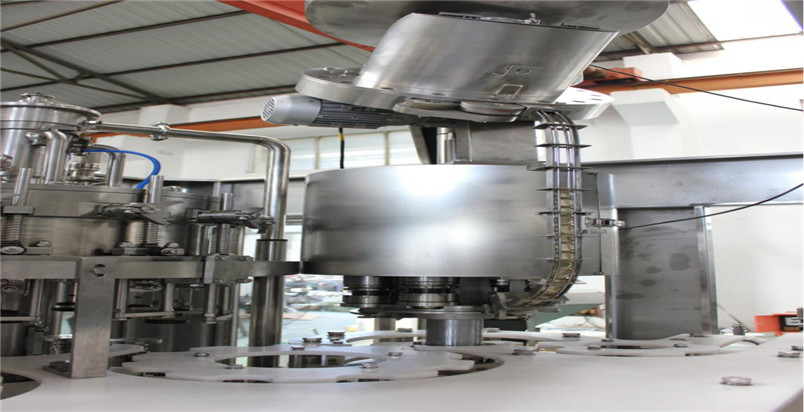

1. Beer Bottling Machine(3 in 1)

2. Bottle Dryer

2. Bottle Dryer

| NO | Product Name | QTY | Capacity(330/500ml) | Capacity(330/500ml) | Capacity(330/500ml) | Capacity(1L) |

| 1. | Beer bottling machine (3 in 1) | 1 | 1000bottle/h | 2000bottle/h | 3000bottle/h | 4000bottle/h |

| 2. | Conveyors | 10meter | / | / | / | / |

| 3. | Bottle dryer | 1 | / | / | / | / |

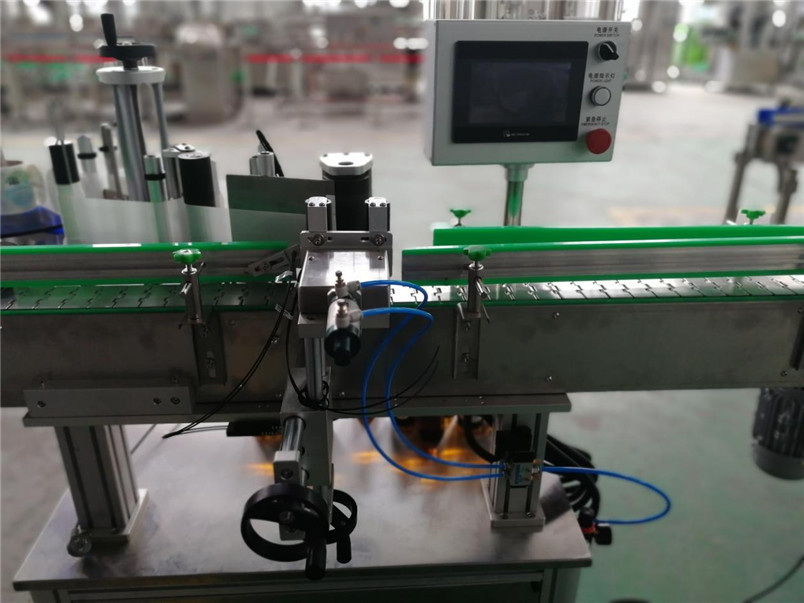

| 4. | Automatic Labeling machine | 1 | / | / | / | / |

| 5. | Stainless steel platform | 2 | / | / | / | / |

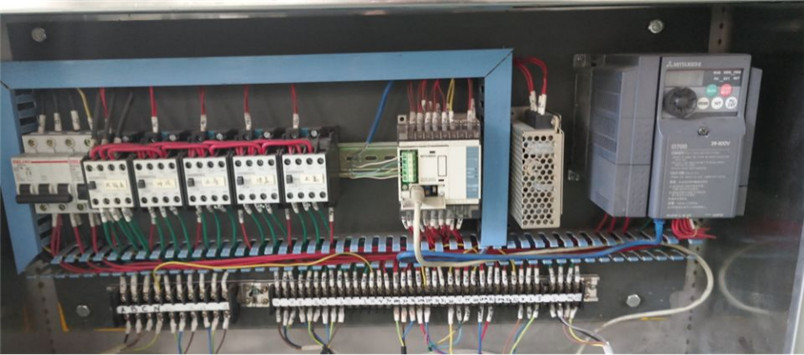

Main Elements List:

| NO. | PART NAME | BRAND | COUNTRY |

| 1 | Main Motor | SEW | Germany |

| 2 | Transducer | MITSUBISHI | Japan |

| 3 | Programmable Logic Controller (PLC) | MITSUBISHI | Japan |

| 4 | Touch Screen | MITSUBISHI | Japan |

| 5 | Contactor | SIEMENS | Germany |

| 6 | Photo Sensor | AUTONICS | Korea |

| 7 | Proximity Switch | AUTONICS | Korea |

| 8 | Infrared Heating Lamp | DELIXI | China |

| 9 | Infrared Temperature Checker | DELIXI | China |

| 10 | Encoder | KOYO | Japan |

| 11 | Limit Switch | OMRON | Japan |

| 12 | Photoelectric Switch | OPTEX | Japan |

| 13 | Intermediate Relay | OMRON | Japan |

| 14 | Torque Clutch | MAYR | Germany |

| 15 | Electromagnetic Valve | FESTO | Germany |

| 16 | Stretch Cylinder | FESTO | Germany |

How to control the temperature of the fermenter

The PLC or digital displayer is connected to the PT100 temperature sensor installed on the tank through the signal line to control the temperature.

What factors need to be considered when choosing a set of bar beer brewing equipment

1. The consumption of beer

2. Site conditions

3. Estimated investment

4. Types of winemaking

5. Daily brewing batches

6. Brewing process

7. Wine selling equipment

8. The aesthetics of the equipment

Shandong Zeren Machinery Equipment Co., Ltd. is an equipment manufacturer focusing on biological fermentation industry

Copyright © Shandong Zeren Machinery Equipment Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support: