Before cleaning the container and pipeline with cleaning agent, rinse with water to remove most of the dirt, and then clean with cleaning agent to save the amount of cleaning agent. After cleaning with cleaning agent, then rinse with water; if sterilization is required, use bactericide to sterilize, and then rinse with sterile water; if cleaning and sterilizing mixture is used, clean and sterilize once, Rinse with bacteria water.

In the past, the traditional cleaning method required dismantling the pipe, cleaning it by hand with a brush, and then washing away the dirt with water. This cleaning method is labor-intensive, time-consuming and difficult to achieve aseptic requirements. At present, the CIP in-situ cleaning method is widely used. Its advantage is that it does not need to disassemble the pipeline and equipment. The cleaning liquid is connected with the cleaned equipment and pipeline with fixed pipelines to form a closed system, and then cyclic cleaning replaces manual cleaning. operation, and make the whole cleaning process transition to automation and program control, and the cleaning effect has a leap forward compared with the past. Simultaneously, since people do not need to enter the container, it is also easy to achieve sterility.

The in-situ cleaning method is mainly used for large airtight containers, such as fermentation tanks, wine storage tanks, saccharification pots, wort boiling pots, whirling sedimentation tanks and tank cars and other large-capacity equipment, which require a large amount of cleaning fluid . Its principle is to spray the cleaning liquid onto the entire inner surface of the container to clean and sterilize.

1. Cleaning agent

According to the way the cleaning agent is used, it can be divided into two types: one-time use and recycle use. With the one-time cleaning method, the system to be cleaned is less likely to be polluted, and the cleaning agent concentration is low, but the operation cost is high and the energy consumption is high. This method is often used in occasions where the scope of the cleaning system is small or the cleaning degree is required to be high. The other is the cleaning method of recycling the cleaning agent. This method is widely used in breweries. The amount of cleaning agent is saved and the energy consumption is low. However, the one-time investment is large and it needs to occupy a large space.

2. Cleaning temperature

According to the cleaning operation temperature, it can be divided into cold cleaning and hot cleaning. Cold cleaning is often used for cleaning large containers, mainly for the safety of large tank operations. For the fermenter, under no circumstances should the cleaning temperature be higher than 45°C, otherwise, it may cause damage to the fermenter. Thermal cleaning is often used for cleaning small containers, pipelines and equipment.

3. Type of cleaning device

Generally, a tank washer is used to clean the conical tank. The cleaning liquid is sprayed onto the inner surface of the tank through the tank washer, and then the cleaning liquid flows down along the tank wall. Generally, the cleaning solution will form a thin film and adhere to the tank wall, so the effect of mechanical action is very small, and the cleaning effect is mainly achieved by the chemical action of the cleaning agent. There are mainly three types of cleaning devices for conical tanks, namely, fixed ball washing, rotary ball washing and rotary jet tank washing. In the cleaning work, the cleaning device plays a vital role. Therefore, it is necessary to choose a suitable cleaning device according to your own production characteristics, process requirements, and the shape and size of the fermentation vessel.

(1) Fixed washing ball

Fixed washing ball

The fixed washing ball is the most commonly used cleaning device and is the standard configuration of most equipment. Since the cleaning liquid sprayed by the fixed washing ball can only hit various points on the inner wall, the area between the jets must be washed with a large amount of water, alkali and acid. required cleaning effect. Therefore, the cleaning cost is high. In addition, this form of cleaning itself has some unreliable factors: on the one hand, the free circulation surface of the fixed washing ball will be blocked by particles, thus producing an undesired sieve effect; on the other hand, The clogged hole on the washing ball will inevitably produce a hole on the inner wall of the large tank

Blind area; moreover, the fixed wash ball does not produce any mechanical action on the lower part of the large tank, and cannot satisfactorily remove tight attachments in the lower 1/3 area.

When cleaning with a fixed porous spherical nozzle, the lotion is sprayed onto the top and upper wall of the container, and the dirt on the lower wall is removed when the lotion flows down by the action of gravity. With this cleaning method, the pressure of the cleaning liquid is relatively low (0.15~0.25MPa), the impact force on the inner wall of the equipment is small, and the descaling effect is relatively small.

(2)Rotary washing ball

Rotary washing ball

Rotary wash balls can produce better mechanical action than stationary wash balls. The rotary washing ball can produce a directional liquid jet, which can form a high impact force and wetting ability. Compared with the fixed washing ball, the rotating washing ball adopts slit-shaped openings to generate fan-shaped jets on the inner surface of the tank. This fan-shaped jet can remove product residues on the inner surface of the large tank through shearing action, and the area of action is also significantly larger than that of the fixed washing ball. Through additional mechanical action, the cleaning time of CIP can be shortened and the concentration of cleaning solution can be reduced. In addition, because the blocking effect of the gap is significantly lower than that of the round hole of the fixed washing ball, the risk of blockage of the entire flow surface is also significantly reduced. The rotary washing ball is suitable for large tanks with a diameter of no more than 4.5m, and the working pressure is 0.15~0.3MPa. If the working pressure is too high, it will cause the washing ball to rotate too fast, which will affect the cleaning effect due to the atomization of the jet. The best working pressure of rotary washing ball and fixed washing ball is

0.15~0.3 MPa.

(3)Rotary Jet Tank Washer

Rotary Jet Tank Washer

The mechanical action of flushing can be enhanced by using a rotary jet tank washer. If the diameter of the fermenter is greater than 4.5m, or the dirt on the inner surface of the tank has strong adhesion, it is recommended not to use the rotary washing ball, but to use the rotary jet tank washer (Figure 8-8). The working pressure of this cleaning device is 0.3-0.5MPa, and the cleaning range can reach up to 16m. It can provide intensive cleaning within a 360° range within a given time, the maximum working temperature is 95°C, and the specification of the cleaning fermenter can reach 700m3. The working principle is that the cleaning fluid flows through the turbine, the gear unit and the spray head itself, and then spreads to 4 or 8 nozzles to produce a high-density spray. With the rotation of the tank washer, the network track formed becomes denser and denser. After 8 rotations of the can washer, the mesh pattern has reached the best tightness. At this point, it can be assumed that any point on the tank is sprayed by the jet. Through the above-mentioned working method of the tank washer, it can be calculated in advance exactly how long each point in the tank will be washed after passing through and how much water and cleaning agent are used. In addition, the rotational movement of the tank washer can be detected with special sensors and evaluated with a corresponding computer program.

Due to the difference in the speed of the spray head and nozzle, the spray will produce a controlled pattern to ensure that the area within the cleaning distance is effectively cleaned. The complete cleaning pattern is generated after 43 revolutions of the nozzle, and then restarts. In addition, 2 external nozzles ensure cleaning of the outer surface of the spray head itself.

The cleaning fluid flow rate of each spherical cleaner is about 12m³/h. The radius of action of the special spherical cleaner can reach 5m, and the flow rate of cleaning liquid can reach 60m³/h. When the equipment to be cleaned is dirty and the diameter of the tank is large (greater than 2m), generally

The rotary jet cleaner is used to increase the cleaning radius by increasing the outlet pressure of the cleaner (0.7MPa). Rotary jet washers allow for lower wash fluid flow rates compared to ball washers.

The advantages of using tank washer are: compared with other cleaning methods, it has powerful spraying and high-efficiency cleaning effect; it can save cleaning time; the amount of water and cleaning agent is reduced; self-cleaning design, no self-pollution.

Use a high-pressure rotary jet to remove the dirt and organic deposits on the inner wall of the wort boiling pot and the heater, or to clean the beer stones on the stainless steel fermentation tank and beer tank car, and use sodium gluconate or EDTA alkaline cleaning agent. For enamel containers, non-corrosive soda ash and sodium silicate can be used instead of caustic soda in the cleaning solution, and the effect is also very good.

1. Key points of CIP system design

(1) The volume of the CIP storage tank should at least meet the requirements of the 10min working flow (volume meter) of the cleaning pump.

(2) If the CIP system needs a return pump to achieve the return cycle, the capacity of the return pump should be 20% to 30% higher than that of the output pump to prevent the CIP liquid from accumulating in the system.

(3) The storage tank itself should have a cleaning device and a sewage discharge device.

(4) The storage tank should be equipped with an overflow port and a vent hole, and the vent holes should be directed outdoors.

(5 ) The CIP equipment group should have an observation corridor with good ventilation and lighting conditions.

(6) Acid, alkali and other storage tanks with corrosive media must have obvious safety signs and emergency signs.

(7) There should be measuring and displaying instruments such as liquid level gauges and thermometers in the tank to monitor the operation of the CIP system.

(8) Sampling valves should be installed in storage tanks for acids, alkalis, and sterilants, and the concentration should be checked regularly.

(9) It is recommended to use a double-seat valve to avoid mixing of CIP fluids.

2. Design of CIP cleaning system

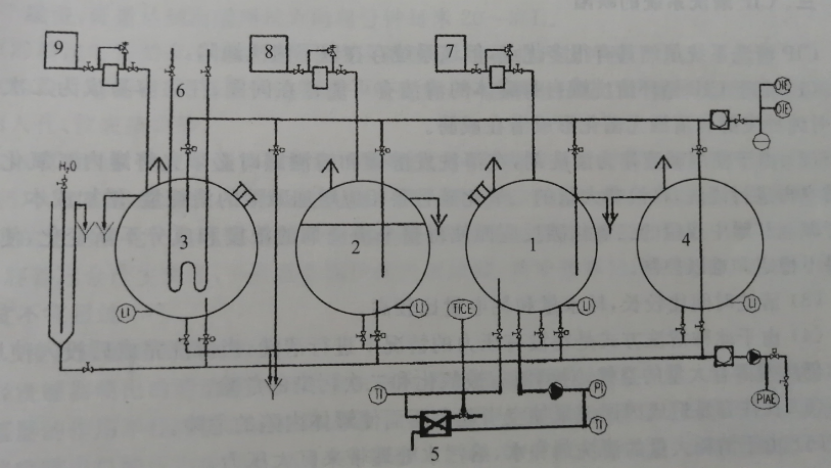

The typical process of CIP cleaning system is shown in the figure

1-Alkali recovery tank 2-acid cleaner collection tank 3-bactericide collection tank 4-recovery water tank 5-alkali heater

6-Fungicide cooling 7-Concentrated alkali storage tank 8-Acid storage tank 9-Fungicide storage tank

The main equipment in the system are:

(1) Recycling water tank. It comes from the sterile water of the last wash, which is recycled and stored for pre-washing of other systems.

(2) Alkali tank. Store the lye or alkaline detergent prepared according to the process regulations. Generally, there is a heater outside the tank, which is heated by forced circulation, and the heat exchange rate is relatively high. If the thermal cleaning process is adopted, the external heater is heated by steam to heat the lye to a predetermined temperature. The purpose of alkaline cleaning is to remove the organic dirt generated in the system.

(3) Acid storage tank. Store acidic detergents. The purpose of pickling is to remove inorganic dirt generated in the system, such as calcium salts, magnesium salts, etc.

(4) Fungicide tank. Store the fungicide at the specified concentration.

(5) Sterile water tank. The water can be pretreated by sand filtration, and then sterilized by ultraviolet light. The sterile water is used to flush the residual fungicides to improve the aseptic level of the system. The above 5 storage tanks are the minimum number of containers required by the CIP system. Auxiliary facilities include cleaning pumps, external heaters (tube shell or thin plate), acid, alkali, bactericide and sterile water adding devices. Before the cleaning agent is sent to the cleaning system, a pipe filter should be installed to avoid bringing the dirt in the CIP tank back to the cleaning system.

3. Operation of CIP system

(1) The cleaning agent and sterilizing agent should be checked twice a week. For the occasions where the concentration fluctuates greatly during the work process, the cleaning agent should be checked once a day.

(2) CIP sampling inspection items include the solid content and color in the cleaning agent to evaluate the degree of pollution.

(3) In the case of normal operation, the cleaning agent in the CIP storage tank is discharged once every 6 to 8 weeks.

(4) Establish a regular calibration system to ensure the reliable operation of the measuring components of the CIP system.

(5) The equipment should be inspected and maintained normally, the scale deposited in the tank should be cleaned, the degree of corrosion should be assessed, and safe operation should be ensured.

Each section of the modern brewery is equipped with an independent CIP cleaning device. The CIP system is generally divided into: wort preparation part, plate heat exchanger and pipeline to the entrance of the fermenter, yeast expansion system, fermenter area, filtration system, sake tank and auxiliary pipeline, filling part, etc.

Although the CIP cleaning system has many advantages, the system has the following cleaning defects:

(1) Since the cleaning of the tank body of the CIP cycle cleaning tank itself may have problems, it is often easy to become a secondary pollution source, forming a potential threat to purebred fermentation and sake sterility.

(2) Due to the use of lye as a cleaning agent, when cleaning the fermentation tank and sake tank, the carbon dioxide in the tank must be released and emptied before cleaning, which will waste a lot of carbon dioxide and increase the consumption of lye accordingly, increasing the cost . At the same time, the concentration and composition of the entire cleaning agent are constantly changing due to the reaction of the lye and the residual carbon dioxide in the tank, making the cleaning effect unstable and difficult to control.

(3) The cleaning time is relatively long, and the water consumption and power consumption are relatively high.

(4) Since this kind of cleaning method is to clean under the situation of no pressure, when the cleaning is completed and put into use, there is still a large amount of air remaining in the tank, which has the danger of oxidation and secondary pollution to the wine liquid.

(5) It is often easy to cause the danger of sinking the tank due to the negative pressure caused by the evacuation of the return pump.

(6) Due to the consumption of a large amount of cleaning agent and water, it brings great pressure to sewage treatment.

Shandong Zeren Machinery Equipment Co., Ltd. is an equipment manufacturer focusing on biological fermentation industry

Copyright © Shandong Zeren Machinery Equipment Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support:

1500L Vodka Distiller

1500L Vodka Distiller

Kambucha Brewing Equipment

Kambucha Brewing Equipment

500L Nano Brewing Equipment

500L Nano Brewing Equipment

1000l 4 vessels beer brewing equipment system

1000l 4 vessels beer brewing equipment system

Semi-auto Can Washing & Filling & Capping Machine

Semi-auto Can Washing & Filling & Capping Machine

150L home brewery

150L home brewery

1000L brewery equipment

1000L brewery equipment

500L Brewery Equipment

500L Brewery Equipment

150L home brewing equipment

150L home brewing equipment

1500L 4 Vessle Brewery Equipment

1500L 4 Vessle Brewery Equipment

1000L Brewery Equipment

1000L Brewery Equipment

50L small brewery

50L small brewery

100L home brewery

100L home brewery

100L home brewing equipment

100L home brewing equipment

60L home brewing equipment

60L home brewing equipment

50L/100L home brewing equipment

50L/100L home brewing equipment

800L Brewery Equipment

800L Brewery Equipment

2500L Turnkey Brewery

2500L Turnkey Brewery

300L brewery equipment

300L brewery equipment

1000L brewery equipment

1000L brewery equipment

50L home brewing equipment

50L home brewing equipment