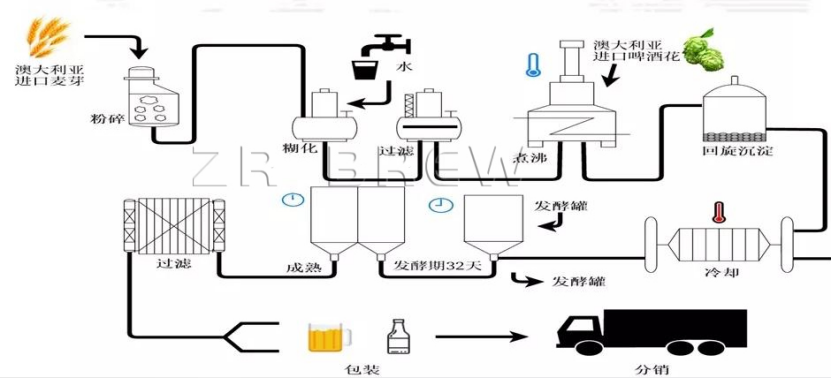

The saccharification time is the time from feeding to wort entering the fermenter, and the maximum interval cannot exceed 6 hours.

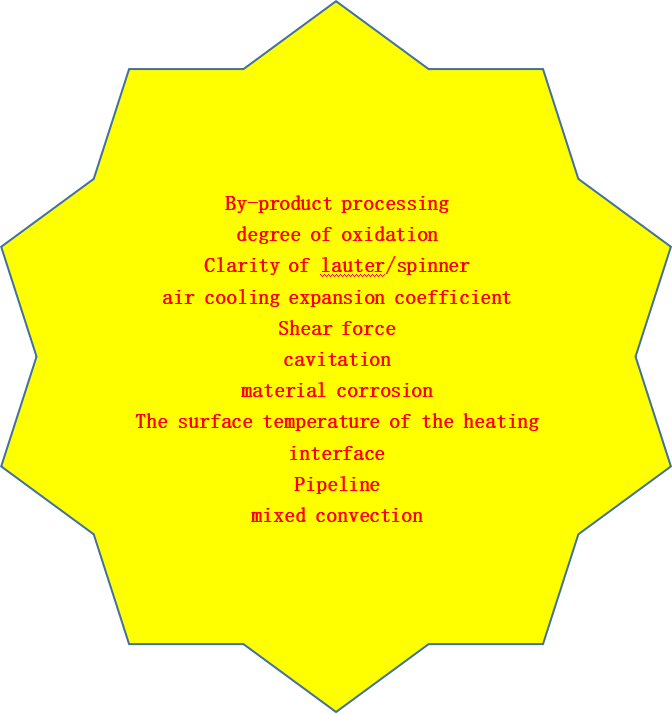

Technological development of the saccharification process

1.Problems that should be paid attention to in the saccharification workshop

By-product processing

degree of oxidation

Clarity of lauter/spinner

air cooling expansion coefficient

Shear force

cavitation

material corrosion

The surface temperature of the heating interface

Pipeline

mixed convection

2.Modern Saccharification Requirements

The right goal: the quality of beer must at least meet the national standard.

(1)good economic benefits

(2)Energy Investment and Conservation Measures

(3)Necessary safety self-control system

(4)Good and comfortable working environment

(5)Less equipment maintenance and maintenance costs

(6)reliable operation

(7)Lower environmental load - the possibility of water and its pollution

(8)Well-maintained equipment, low shear forces

(9)consistent quality

(10)Lower oxygen levels, less gunk - the heated surface is cooler.

(11)High flexibility.

(12)Lower heat load values.

(13)Archives are kept intact and can be searched quickly.

(14)Important premise: The operator should love his job.

3. Several requirements for the saccharification room

(1) The design and acceptance shall be carried out in accordance with the corresponding national standards.

(2) The pipeline design is reasonable, which can transport the mash and wort well.

(3) The pump has no cavitation phenomenon - the pump should be located 0.5m below the lowest liquid level of the equipment.

(4) Use a stirrer with frequency conversion adjustment.

(5) All pump speed controls adopt drive motors adjusted by frequency conversion.

(6) Bottom feeding is adopted.

(7) The oxygen intake should be low during feeding and emptying.

(8) Pipelines and components meet hygienic requirements.

(9) The valve or connecting plate must meet the requirements of HACCP.

(10) The saccharification temperature should be controlled within ±0.2°C of the set value.

(11) Boiling wort is heated at the bottom, and its temperature should be controlled within ±2°C of the set value.

(12) The operation of the cultivator should not only consider the pressure difference, but also the flow of wort.

(13) The saccharification time is the time from feeding to wort entering the fermenter, and the maximum interval cannot exceed 6 hours.

4. How to ensure stable and uniform quality of saccharification

stable production conditions |

| Balanced Production Equipment |

| constant quality |

1. water 2. Malt + accessories 3. crush 4. biological acidification 5. hops 6. thermal energy 7. electricity 8. compressed air 9. production method | 1. Material 2. beer stone 3. to stir 4. Pump 5. pressure 6. liquid properties 7. layered 8. mix 9. flow rate | 1. Yield 2. Iodine value 3.MgSO4 4. Zinc 5. Final 6. Amino Nitrogen 7. Dimethyl sulfide 8. PH value 9. Bitter quality 10. TBA 11. Freezing nitrogen 12. Total nitrogen |

Note: The traditional control method is by controlling the final product; while the new control method is to control the input and production process

5. The traditional saccharification room has the following weaknesses:

(1)Dry crushing ----- classification (9) uneven mixing

(2)Wet crushing -----traditional system (10) Turbidity and solids during filtration

(3)Pulverization------oxidation (11) heat load in whirlpool sedimentation tank

(4)Oxidation of mash and wort (12) suboptimal acidification

(5)Cavitation phenomenon dead ends in pipelines (13) microbial contamination caused by sanitary

(6)High heat load (14) Effect of by-products

(7)The evaporation surface is too large (15) Secondary effect of condensed exhaust steam

(8)Return of condensed water in the pot (16) exhaust steam intrusion

5. Good malt quality has many advantages

More than 40% of beer quality is determined by malt. The advantages of good malt quality are as follows:

operate | finished beer |

The saccharification process is brief Low energy consumption shorter filter time higher yield Promote fermentation good filtration performance good stability | light shade good foam fewer fermentation by-products good smell Pure, full-bodied moderate bitterness longer shelf life good taste stability |

Technological development of the saccharification process

1. Key issues in the saccharification process

(1) The oxidation problem in the process from saccharification feeding to mash extraction.

(2) Mechanical action by stirring, pumping and poor piping.

(3) Poor convection and mixing of the mash (beer stones cause bad taste in beer).

(4) Excessive heating temperature, coupled with poor convection (heating interface temperature).

(5) Cavitation of the pump.

(6) The dead zone in the pipeline is easy to acidify the wort and form butyric acid.

(7) When the mash is boiled, the steam will remove the bad substances.

(8) The harm caused by optimized saccharification and too short leaching and saccharification process will lead to weak beer taste and lose the characteristics of beer.

(9) From an economic point of view, it can be adopted: use turbid residual water after washing, add hot water process or partial mash method to increase the feeding temperature and carry out acidification treatment.

2. Problems in actual production

(1) People do not want to change the existing saccharification program due to the influence of traditional technology and "set automatic program".

(2) Improve iodine value.

(3) There will always be low α-amino nitrogen and zinc content in wort.

(4) Colloidal substances and binding gels caused by saccharification will affect wort and beer filtration.

(5) Uncontrollable oxidation.

(6) Different beer varieties will cause different hazards.

(7) Mechanical action.

(8) Considering beer foam and a-amino nitrogen, the feeding temperature is critical.

Shandong Zeren Machinery Equipment Co., Ltd. is an equipment manufacturer focusing on biological fermentation industry

Copyright © Shandong Zeren Machinery Equipment Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support:

1500L Vodka Distiller

1500L Vodka Distiller

Kambucha Brewing Equipment

Kambucha Brewing Equipment

500L Nano Brewing Equipment

500L Nano Brewing Equipment

1000l 4 vessels beer brewing equipment system

1000l 4 vessels beer brewing equipment system

Semi-auto Can Washing & Filling & Capping Machine

Semi-auto Can Washing & Filling & Capping Machine

1000L brewery equipment

1000L brewery equipment

100L home beer brewing equipment

100L home beer brewing equipment

500L Brewery Equipment

500L Brewery Equipment

150L home brewing equipment

150L home brewing equipment

1500L 4 Vessle Brewery Equipment

1500L 4 Vessle Brewery Equipment

1000L Brewery Equipment

1000L Brewery Equipment

100L home brewing equipment

100L home brewing equipment

60L home brewing equipment

60L home brewing equipment

50L/100L home brewing equipment

50L/100L home brewing equipment

800L Brewery Equipment

800L Brewery Equipment

2500L Turnkey Brewery

2500L Turnkey Brewery

300L brewery equipment

300L brewery equipment

1000L brewery equipment

1000L brewery equipment

50L home brewing equipment

50L home brewing equipment